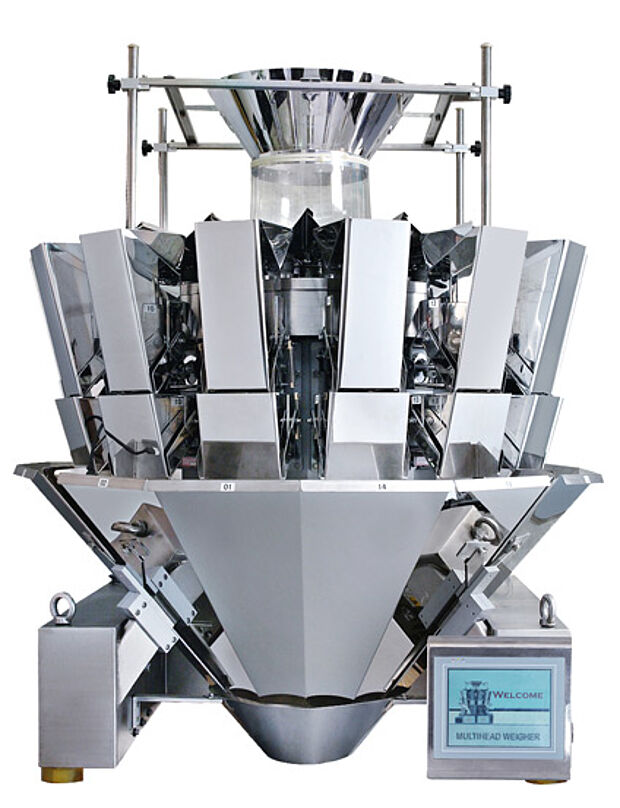

Precision and efficiency with our multihead weighers

Optimize your packaging processes with our state-of-the-art multihead weighers. These scales are specially designed to ensure the highest accuracy and speed when filling and packaging products.

Why our multihead weighers?

- Highest precision: Our multihead weighers offer exceptional accuracy, ensuring that every product has exactly the right weight.

- Fast processing: With high speed and efficiency, you can significantly increase your production capacity.

- Versatility: Ideal for a wide range of products, from food to non-food items.

- Ease of use: Easy to use and maintain thanks to an intuitive user interface and robust design.

- Cost efficiency: Reduce waste and maximize your profits through precise and reliable weighing processes.

Find out more about our multihead weighers and how they can revolutionize your packaging processes. Contact our team of experts for individual advice and a non-binding offer.

- Possible weights from 1 - 3.500 gram

- max. 130 weighings / minute

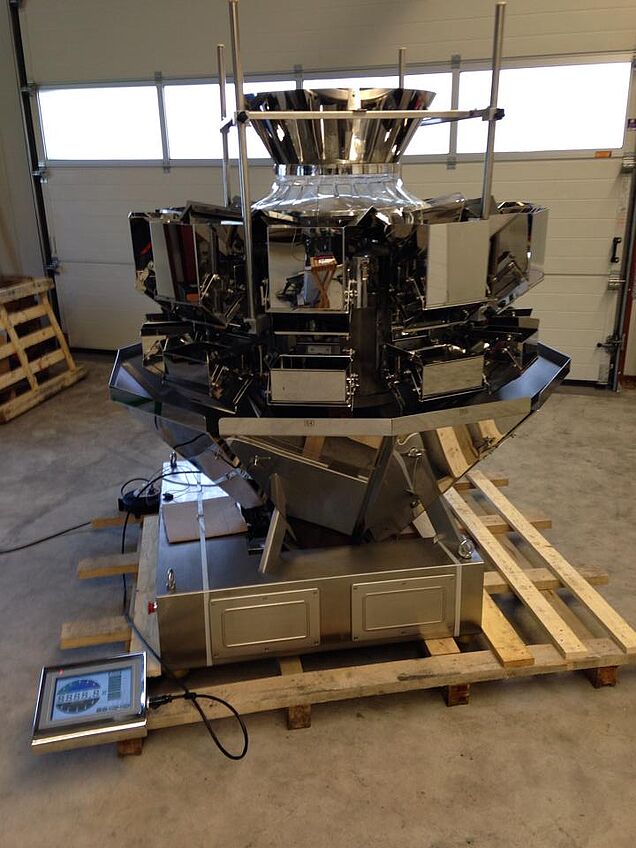

- Multilanguage touch-screen color control panel

- Easy operation, for setting speed, target weight etc.

- Storage for 50 programs

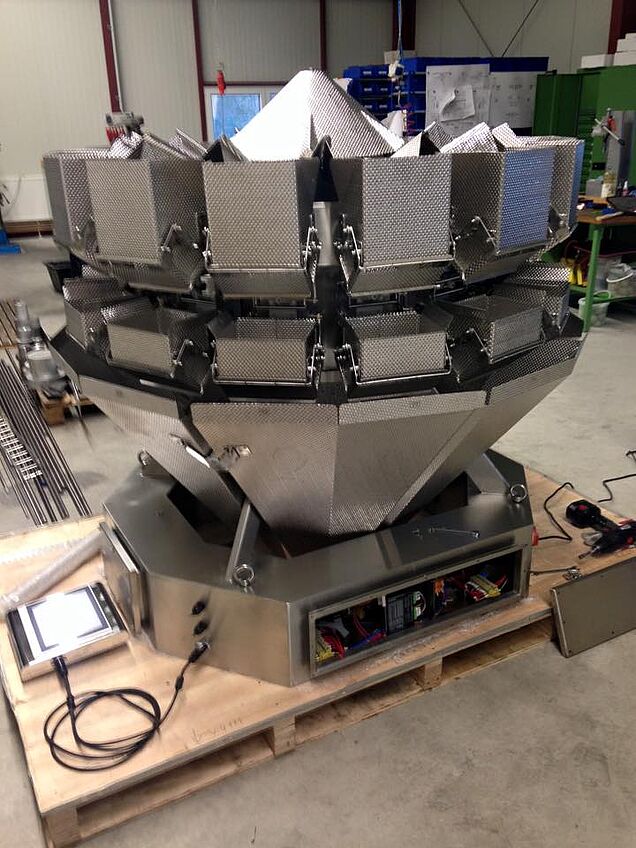

- Easy to dismantle and toolfree cleaning

- Synchronisation with all packaging machines

- Complete stainless steel construction

- Steppermotor controlled opening of buckets

- no compressed air needed

- Loadcell under topcone for feeding control

Technical data

| TYPE | MAXIMUM WEIGHT (g) | VOLUME WEIGHING HOPPER (l) | MAXIMUM VOLUME PORTION (l) | SPEED (Weighings per minute) |

|---|---|---|---|---|

| HT-C10XS | 60 | 0,3 | ||

| HT-C10S | 300 | 0,5 | 1 | 70 |

| HT-C10 | 1000 | 1,6 | ||

| HT-C10XL | 2500 | 2,5 | ||

| HT-C10XXL | 3500 | 5 | ||

| HT-C14XS | 60 | 0,3 | ||

| HT-C14S | 300 | 0,5 | 1 | 130 |

| HT-C14 | 1000 | 1,6 | 3 | 120 |

| HT-C14XL | 2500 | 2,5 | 5 | 100 |

| HT-C14XXL | 3500 | 5 | 10 | 80 |

| HT-C16S (TWIN) | 300 | 0,5 | ||

| HT-C20 (TWIN) | 1000 | 1,6 | ||

| HT-C20XL (TWIN) | 2500 | 2,5 | ||

| HT-C24S (MIX) | 300 | 0,5 | ||

| HT-C24XL (MIX) | 2500 | 2,5 | ||

| HT-C32 (MIX) | 300 | 0,5 | ||

| HT-C32XL (MIX) | 2500 | 2,5 |