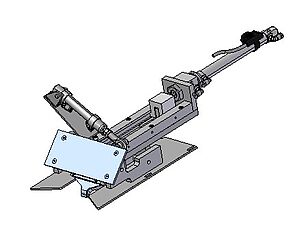

Label feed AZxxx

for wine glass labels

The label feed AZxxx is an optional pneumatic label insertion device for our ultrasonic net sealing machines, whereby the desired label length can be between 100mm and 160mm.

The so-called "wine glass labels" made of PE are fed to the welding station and are inseparably connected to the packacke by ultrasonic welding. With our thermo- / thermotransfer printer, the labels can be printed on one side with the desired data, such as EAN code, before being fed into the ultrasonic net sealing machine.

The labels, which are wound on a roll in a container (optional), are either unwound from the roll by our thermo- / thermotransfer printer (optional) or from the AZxxx label feeder and fed to the individual packs in time with the ultrasonic net sealing machine.

After the label has been sealed to the package, the label is separated from the roll by a pneumatically operated knife.

The process is completely electronically monitored so that packages without a label can be excluded.

Technical data

| Label length minimal: | 100mm |

| Label length maximal: | 160mm |

| Label width minimal: | 40mm |

| Label width maximal: | 60mm |

| Compressed air: | min. 6bar cleaned, not oiled |

| Speed / Capacity: | >50 labels / min. |