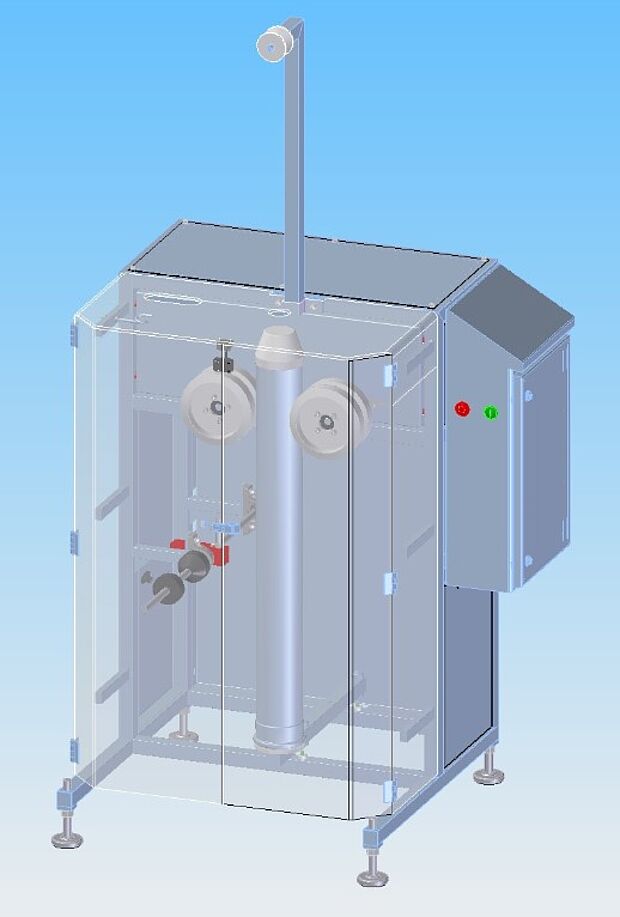

Tube loader TLxxx

The tube loader TLxxx was specially developed. The mesh material is brought from the roll directly onto the mesh tubes using rubber wheels. After an empty net tube has been inserted into the net pulling device and the protective door is closed, the filling of the net tube is started by pressing the "start button". The rubber wheels close pneumatically and adapt to the net tube. The drive then starts and the rubber wheels fill the network tube for a pre-set time. In order to ensure that the net tube is filled evenly with very tight net material, the net tube can optionally be evenly lowered during filling. After approx. 50-60 seconds, a network tube is completely filled. The net roll is braked pneumatically after the winding process has ended.

A frequency converter has been used for the drive since January 2005. This means that even very sensitive networks, e.g. Garlic nets etc., are automatically placed on the net tubes. The drive is accelerated and braked via a ramp, which ensures optimal filling of the network tube.

Optionally, the filling of the network tubes can be monitored electronically.

Advantages at a glance:

- easiest handling

- robust and compact design

- different tube diameters possible

- Special versions possible