Control cabinet & control system construction

No matter whether it is a fully automated production machine using digital technology or a classic production line based on analogue mechanics: Control systems and control cabinets are an essential part of all industrial plants. Accordingly, it is important to leave development and construction to true professionals. Especially in larger companies, the design of control systems and control cabinets quickly becomes very complex. Exact planning using CAD software and the precise implementation of the designs created in this way are the keys to success. After all, practical control cabinet construction is faster and safer if the preceding planning is correct.

What is a control cabinet?

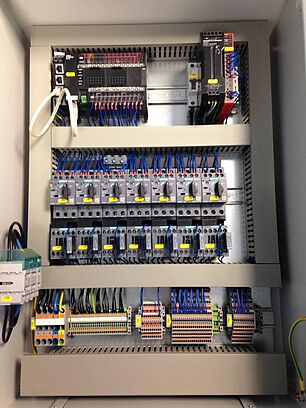

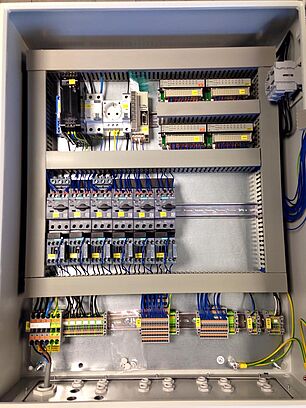

Control cabinets, as used in industry, are used to house and protect all electronic and electrical components of a plant that are not installed in the actual machine. This is particularly important in larger plants, where different process engineering systems are usually operated in parallel and work together. In automated and semi-automated systems in particular, the control cabinets serve not least to exchange signals between the different systems.

For this purpose, active technology is now sometimes installed directly in the control cabinets and planned into the control cabinet's circuit diagram. The answer to the question: "What is a control cabinet?" has therefore changed considerably over time. Overlaps with control cabinet construction are unavoidable. Nevertheless, pure terminal boxes, which are little more than distribution boxes for power and other cables, continue to play a decisive role in the planning of control cabinet construction. At HeickTech, we typically plan control cabinets and control systems together to simplify cabling.

Professional control cabinet construction

We design all kinds of control cabinets for you: from small distribution boards and terminal boxes to connection and individual boxes to extensive series cabinets and, of course, control panels. In the process, we develop an individual customised control cabinet for you. Detailed tests of the finished circuits are, of course, also part of our all-round service. We are also happy to modernise existing control cabinets for you, for example in the case of retrofitting programmable logic controllers (PLCs).

Of course, we do not limit ourselves to electrical control cabinet construction: we also install communication buses and cabling for you, for example in the form of Industrial Ethernet. This plays a particularly important role in the construction of control cabinets for automated systems. By laying current-carrying lines and other cables together, you save space and simplify maintenance.

It is also important for safety reasons to have the switch cabinet construction carried out by an expert. When building electrical control cabinets, each component must be placed with centimetre or, in many cases, even millimetre precision. At HeickTech we have many years of experience, both in dealing with classic purely electrical circuits and with modern PLC systems and digital technology. All current-carrying connections are protected by us in such a way that no accidental contact with them is possible. Access for maintenance and repairs is easy and quick.

Precise planning and execution

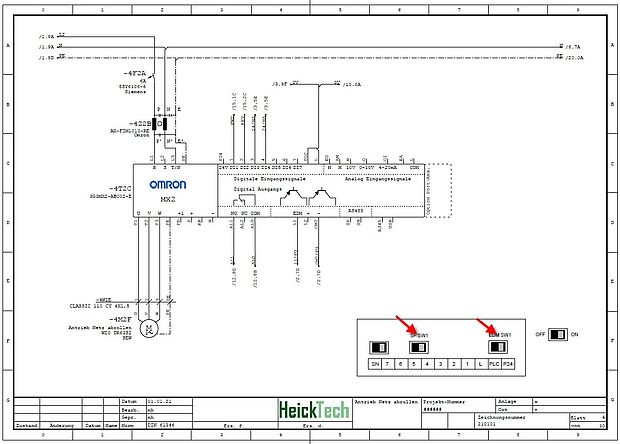

When building control systems and control cabinets, our first priority is the exact planning of the technology. Using CAE and CAD software, we develop precise construction plans for the control cabinets to be implemented in practice. We rely primarily on the market-dominating software solutions from EPlan and WsCAD. From our point of view, EPlan switchgear cabinet construction makes sense not only because of the excellent quality of the software, but also because the designs created can be used independently of us as a service provider. We want to convince you with the quality of our work and not bind you to us by lock-in. Within the scope of our retrofitting services, we naturally also understand how to expand existing circuit diagrams. In doing so, we naturally check all designs once again and ensure that the currently valid safety standards are adhered to before we implement the EPlan control cabinet assembly for you.

During the actual construction of the switch cabinet, we then follow the plans exactly. We use CNC machines to drill holes with millimetre precision. We also lay rails precisely. In addition, we naturally ensure that all connections, rails and cables are labelled according to the construction plan. For future maintenance or expansion of the technology, new employees can then also use the circuit diagram of the control cabinet and rely on the exact implementation.

Quality standards

Safety plays a decisive role in the construction of control systems and control cabinets. When building electrical control cabinets and control systems, we always follow the DIN EN 61439 standard (the successor standard to DIN EN 60439). In particular, this means that our circuits and systems function safely and reliably even under high loads. In addition, we guarantee in this way that all current-carrying components are optimally protected so that, for example, moisture, dust or even radiation influences do not reach the sensitive components in an emergency. Accidental contact of employees with the switching technology can also be ruled out through proper installation and protection. This is important not least for reasons of labour law.

Within the scope of extensive load tests, we ensure that all components function perfectly before the system is put into operation. Of course, we check the functionality of the circuitry even before the actual control cabinet construction by precisely evaluating the circuits with the help of EPlan. This reduces unnecessary effort in the construction of electrical control cabinets and control systems. In this way, we ensure that we can develop and build the circuit diagram and control cabinet for you more quickly and efficiently. Because of course we know how important it is for our customers that the control system and switch cabinet construction is carried out as quickly as possible without compromising on safety and quality.

Do you have any further questions about us and our control cabinet construction services? We would be happy to hear from you by phone, e-mail or via our contact form. We will be happy to answer any questions you may have about EPlan control cabinet construction and, of course, we will also prepare an individual offer for your customised control cabinet.