Ultrasonic net sealing

since 1995

Monomaterial packaging

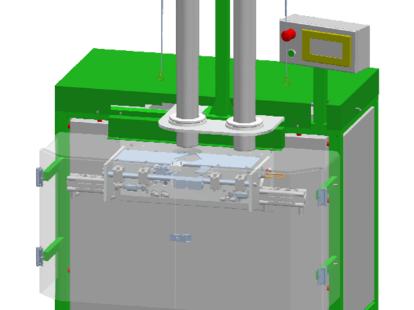

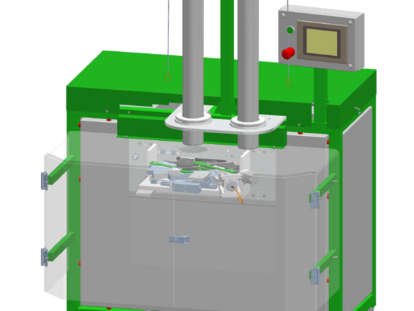

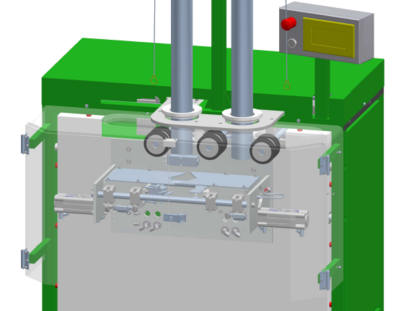

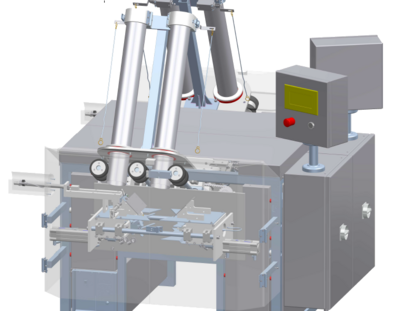

Due to robust and compact construction and by applying innovative, process oriented ultrasonic generators with automatic frequency regulation and using the most sophisticated parts for automation and motion control our ultrasonic net sealing machines are outstanding in capacity and reliability.

The capacity of our machines is higher than 100 bags per minute depending on the machine type. The machines are continuously improved and today we can offer the optimum solution for almost any product to be packed in net.

Ultrasonic welding is an advanced welding technique that offers numerous benefits and is widely used in various industries. Here are some of the key advantages:

- High precision: Ultrasonic welding enables precise and controlled joining of materials, which is particularly beneficial for small and delicate components.

- Speed: The welding process is extremely fast, which reduces production times and increases efficiency.

- No additives: No additional materials such as adhesives or solder are required, which reduces costs and reduces environmental impact.

- Clean and safe: Since there are no open flames or sparks, the process is safe and clean, which improves the working environment.

- Versatility: Ultrasonic welding can be used on a wide range of materials, including plastics, metals and textiles.

- Energy efficiency: The process is energy efficient because only the areas to be joined are heated, minimizing energy consumption.

- High strength: The joints created by ultrasonic welding are strong and durable, which improves the quality of the final products.

Our ultrasonic net packaging machines are compatible with most net materials - even compostable PLA organic nets, which are fully composted within a few weeks, can be sealed with our machines.