Retrofit

Plant modernisation

With the ever faster approaching wave of Industry 4.0, the retrofitting of existing production plants is also becoming more exciting again. At HeickTech, we specialise in the planning and implementation of automation technology. We are also happy to retrofit existing production systems for you. It does not matter to us whether you are still using an old connection-programmed system without digital technology or an already partially digital system that needs to be renewed in order to remain compatible with new technologies.

Besides improving compatibility with new technologies, a retrofit has other advantages: By replacing old components that are no longer available, you ensure that your system is ready for use again more quickly in the event of a defect. In addition, especially with old systems, efficiency can often be increased and energy consumption reduced accordingly. It is also possible to retrofit programmable logic controllers. But what exactly is retrofitting and how does it work?

What exactly is retrofit?

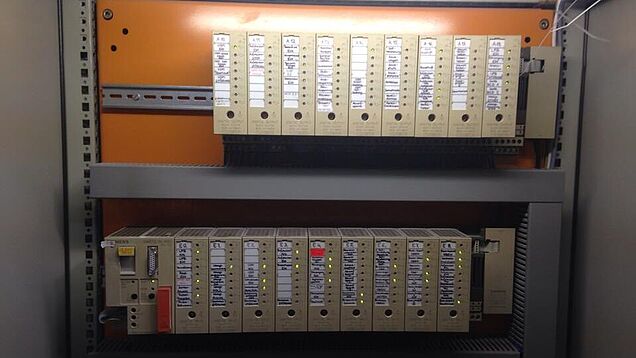

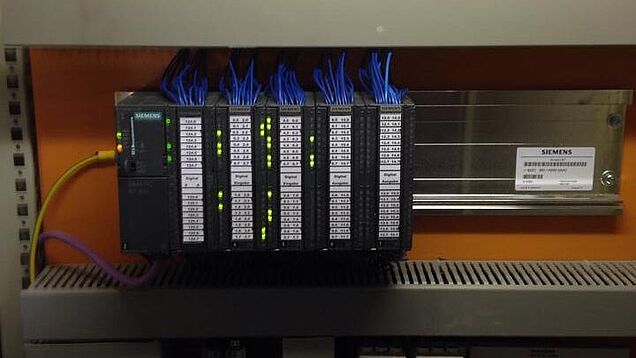

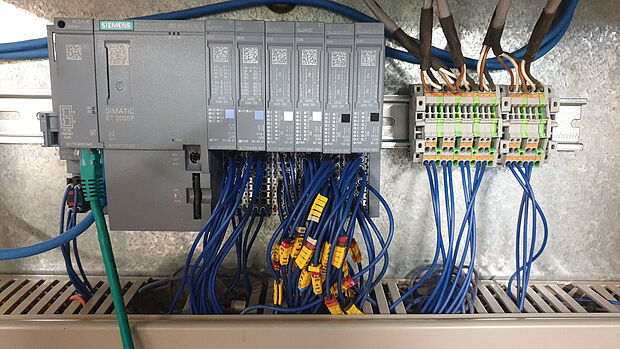

In the industrial sector, retrofitting primarily describes the modernisation of machines. The decisive factor here is that the technology of the machine is retained as far as possible but is expanded with more modern components. In particular, the subsequent installation of digital control units (such as PLCs) is a frequent reason for modernising production plants. But energy savings (for example by retrofitting frequency converters) or the expansion of a plant can also be reasons to have retrofitting carried out. Modernising the machines also makes it possible to use them more effectively in conjunction with other modern equipment. The older systems are thus retrofitted into a modernised ecosystem.

At HeickTech, we specialise primarily in upgrading systems with automation technology and PLC components. However, we are of course also happy to undertake other modernisations for you. Retrofitting machines and modernising production should not be understood as a one-off project, but as a continuous process. In order to meet the challenges of tomorrow, you and your company must remain flexible. Digital technology simplifies this and makes your production leaner and more agile. In many cases, machine modernisation can take place gradually, so that investments in the new technology can be spread out.

The gradual modernisation of production also has the advantage that it allows you to react even more flexibly to further innovations. At HeickTech, within the framework of such process-oriented projects for the retrofitting of machines, we ensure from the outset that the innovations can be easily expanded in the future. By adapting clearly defined open standards and widespread interfaces, we can ensure that your investments today will still pay off in ten years' time.

Efficient further use of your machines

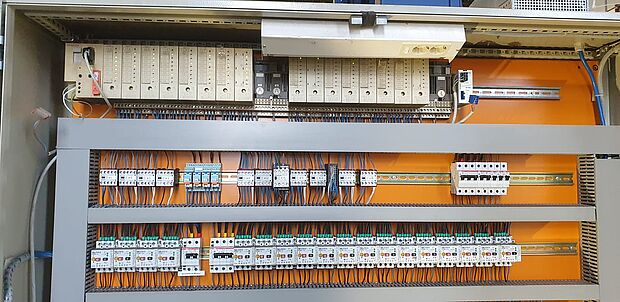

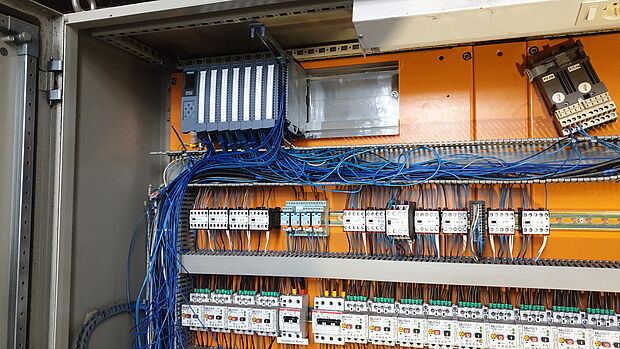

Compared to the purchase of new production facilities, the modernisation of machines is usually much more cost-effective. Since typically only the control and drive technology has to be renewed and other mechanical components can continue to be used unchanged, often only a fraction of the expenditure required for a new purchase is necessary.

At the same time, machine modernisation in many cases means a significant reduction in running costs during operation. On the one hand, this is the case because more efficient drive technologies reduce the power and energy consumption of many machine components. Above all, however, digital technology and automation help to better utilise the existing machines and production capacities. The simplified reprogramming of machines, for example, makes it possible to change over production at much shorter notice. So less time is lost. In addition, PLC components are more space-saving than analogue technologies. This also enables more efficient use of space. Furthermore, automation processes that extend beyond the production line are possible. For example, modern production lines can communicate directly with the company IT. Re-orders of parts or raw materials can thus be organised more efficiently. Machine modernisation thus represents an investment in the future of your company far beyond the actual renewed or expanded equipment.

Adaptation to changes in the legal framework

Retrofitting your machines can also make sense if the legal framework changes. In particular, changes in immission control laws can put a plant that is still functioning excellently out of operation through bureaucratic channels. Changes in occupational health and safety legislation can also make plant modernisation necessary. You can protect your investment by retrofitting and modernising your existing technology. Modernising existing systems with the help of digital technology also makes it easier to replace or reprogram individual components in the future. So even if you are not affected by a change in the law at the moment, machine modernisation can already be useful in order to be able to act more flexibly and quickly in the future. In this way, you can prevent unnecessary downtime on the production line and high costs for any quick adjustments that may then be necessary.

Are you interested in our services for the modernisation of production and machinery? We will be happy to answer any further questions you may have by phone, e-mail or via our contact form. Of course, we will also provide you with an individual offer for the modernisation of the machines after an initial discussion. Of course, we would be happy to combine our retrofit service with our offers for the automation of your production. Of course, we are always interested in long-term partnerships. So after the initial retrofit of the machines, we are also happy to take care of further projects and the maintenance and continued modernisation of the new components.